Don't miss our holiday offer - up to 50% OFF!

How to improve the printing quality of self-adhesive labels

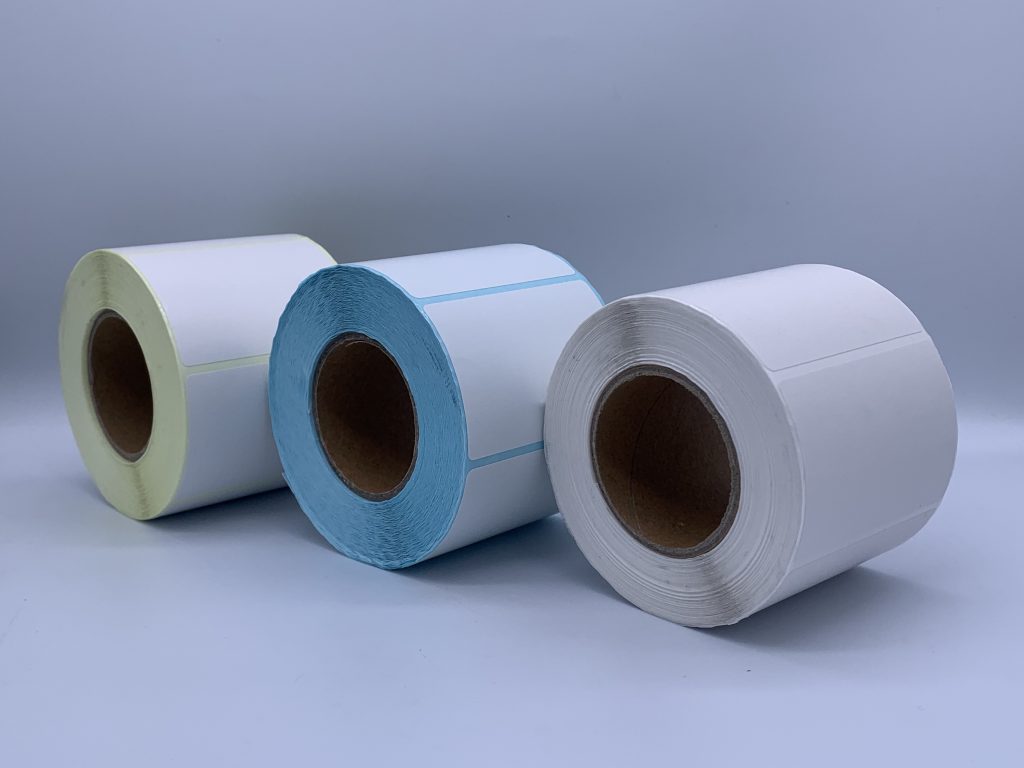

With the continuous improvement of people’s quality of life, the use of self-adhesive labels is getting closer and closer to our lives. The application of self-adhesive labels can be seen everywhere in life. Logistics and express industry logos, supermarket labels, daily chemical packaging, clothing tags, manufacturing, etc. Labels are inseparable from human life. The application of label identification has greatly improved production efficiency and brought great convenience to our life.

Self-adhesive labels are divided into blank labels and printed labels. To print self-adhesive labels, the first thing to ensure is the quality. Only high-quality self-adhesive printing can make our self-adhesive products more popular. We need to know how to print to better improve the quality. Generally speaking, self-adhesive printing needs to be considered in many aspects such as self-adhesive materials, ink application, printing equipment selection, and production process. Today, I will bring you a more professional introduction, 5 ways to improve the quality of self-adhesive printing!

1. Selection of raw materials

When selecting raw materials, be sure to choose high-quality self-adhesive materials with qualified physical and chemical indicators, instead of using expired or unstable physical and chemical indicators. Although the price of the latter is low, but due to the unstable quality of this kind of material, it consumes a lot in each process, and even causes the equipment to be unable to process normally. It wastes a lot of manpower and material resources as well as raw materials. As a result, the processing cost of the finished label It is not necessarily low, and what is more serious is that it may be returned by customers, or even lose customers.

The choice of raw materials should be considered from the following two aspects.

1. Printing and processing characteristics of self-adhesive materials

① The surface gloss and color consistency of the surface material, and the uniformity of density

These indicators determine the uniformity of ink absorption of self-adhesive materials, and also determine the color difference of the same batch of label prints. The coating strength of the surface material determines whether a large amount of paper powder will be produced during printing, and is also an important indicator of the printing quality.

② The uniformity and strength indication of the backing paper and surface material thickness

These indicators are not only related to printing performance, but also important indicators to determine the uniformity of die-cutting, the speed of waste discharge and the breakage of paper edges. If these indicators are too low, the labeling machine cannot produce at high speed.

③ The flatness of the material or the uniformity of the rewinding tension

Whether it is sheet-fed printing or roll printing, the flatness of the material determines whether the paper can be fed, run and registered, and the paper can be delivered correctly during printing. For roll materials, the rewinding tension will play an important role in the flatness of the end surface of the roll material, whether there is glue bleeding, and whether it can be registered correctly.

④ Uniformity of adhesive and silicone oil coating and correct coating amount

These indicators directly affect the peeling force (release force) between the label and the backing paper, and the peeling force directly affects the die-cutting waste discharge and the speed of the machine. The peeling force also determines the labeling status of the label, that is, the application condition. . In addition, the amount of glue applied will also affect the glue penetration of the end surface of the material. Therefore, when purchasing self-adhesive materials, you must carefully inspect them and choose those materials with the appropriate amount of glue and silicon.

2. Application characteristics of self-adhesive materials

①Adhesive type

When choosing a self-adhesive material, you must first determine whether the adhesive required for the self-adhesive label you are making is permanent or removable, whether it is a one-time paste or repositionable, and whether the product is suitable for a dry adhesive label. Whether there are special requirements for the chemical properties of the adhesive, etc.

②The surface condition of the labeling object

What material is the surface of the labeling object, whether it is wood, glass or plastic, whether the surface is smooth or rough, these indicators determine what kind of adhesive should be used.

③The shape and strength of the labeling object

Whether the labeling object is a plane or a curved surface, whether it is a large diameter or a small diameter, whether it is a single curved surface or a spherical surface; whether the object is a rigid body or compressible. These indicators are directly related to the selection of surface materials and adhesives.

④Using environment of self-adhesive labels

Whether the labeled article is used outdoors or indoors, whether it is a high temperature environment or a low temperature environment, whether the use environment is corrosive, whether it is dry or humid. According to these indicators, matching surface materials and adhesives can be selected.

⑤ How to use self-adhesive labels

Is manual labeling or automatic labeling. The labeling method of the label can determine the type of label material, ink type and printing method.

Second, the correct choice of ink

The choice of ink is mainly considered from several aspects such as the quality of the ink itself, the hue, and the wetting of the ink to the substrate—that is, the adhesion fastness of the ink. Although there are many types of self-adhesive materials, their surface materials can basically be divided into three types: paper, aluminum foil, and film. At present, in our country, the printing of self-adhesive labels is mainly based on embossing (roll printing) and offset printing (sheet printing), among which embossing and offset printing are divided into ordinary resin ink printing and UV ink printing.

Generally, paper-based surface materials basically do not have the problem of ink adhesion fastness, so the requirements for ink are not high, and inks of different brands have certain interchangeability and versatility. However, due to the influence of surface tension and different physical properties, aluminum foil and film materials have very strict requirements on inks. The following principles should be followed when selecting inks:

①A self-adhesive material can only use ink produced by one ink supplier at a time, and cannot mix and use similar inks produced by other manufacturers at the same time.

②In principle, each kind of self-adhesive material can only use the corresponding ink that matches it.

③ The additives used should be matched with the ink and cannot be replaced by other types of additives.

④ Pay attention to the service life of the ink, and it is strictly forbidden to use expired ink.

Table 1 is the ink recommendation list. The table recommends the inks used for different types of film fabrics and aluminum foil materials for ordinary letterpress printing, UV letterpress printing, ordinary offset printing, and VV offset printing, and lists the types of commonly used film and aluminum foil materials and major domestic ink suppliers. The model number of the matching ink provided.

Note: (1) The surface tension of the film material should be guaranteed to be above 38-40dyn/cm2, otherwise, there will be problems of ink falling after printing.

(2) The above-mentioned inks should be printed in small batches first, and then used in large quantities after the quality is qualified.

3. Equipment configuration and adjustment

Different types of label printing equipment have different functions due to different hardware configurations, and can print and add label products of different types, materials, and formats. In order to ensure the printing and processing quality of self-adhesive labels, after the selection of raw materials and inks, rational selection of equipment and adjustment of equipment is one of the keys to ensure the quality of label printing.

The labeling machine is a multi-functional device. Only when the printing and processing stations are coordinated and the precision of each part is high can the qualified labels be produced. When using labeling equipment, the following adjustments should be paid attention to:

1. Ink feeding system

Care should be taken to maintain the accuracy of each rubber roller, especially the ink form roller. It is necessary to replace and clean the rubber rollers regularly to make the ink evenly distributed in the system and the ink on the printing plate.

2. Embossing device

The embossing cylinder and embossing platform should be cleaned frequently to keep them flat and smooth. The gears and chains between the embossing cylinder and the embossing platform should be kept in a good meshing state. Only in this way can correct closing pressure, separating pressure and printing register be guaranteed.

3. Traction system

Regardless of whether the label machine is continuously feeding or intermittently feeding, the accuracy of the traction device determines the accuracy of label overprinting. The rotary labeling machine must ensure the accuracy of the transmission gear, and the intermittent labeling machine must ensure the accuracy of the one-way traction roller.

4. Precision of die-cutting device

The precision of the die-cutting device includes the precision of the die-cutting knife and the precision of the die-cutting parts. The accuracy of the die-cutting device not only affects the waste discharge of the label, but also directly affects the application of the label, such as the labeling accuracy during labeling, the speed of the labeling machine, etc. Therefore, it is necessary to adjust the state of the die-cutting device of the label equipment.

Fourth, the formulation of the process route

Determining the label printing process route is a comprehensive issue, which should be considered from the customer’s requirements, label sample conditions, equipment configuration, selected materials and inks, and the specific conditions of the printing factory. The formulation of the process route includes the following contents:

Bronzing first or later;

Glazing or lamination;

Solid printing or screen printing;

Automatic labeling or manual labeling;

Independent printing or hybrid printing;

Large format printing or small format printing;

Half-tone printing or color block and line printing;

Whether the double-sided label is printed on the back or printed on one side;

Whether the label is printed once or twice;

Large format die-cutting or small format die-cutting;

Automatic waste discharge or manual waste discharge;

Whether to print on a blank space on the label or on an ink layer.

There are many problems involved in determining the process route, and the use of a reasonable process route will get twice the result with half the effort. Determining the process route should proceed from reality, and if necessary, a process test should be done to test the printing and processing suitability of the label.

5. Analysis of the application of labels

The determination of a label production process route and the determination of raw materials are related to the customer’s label application effect. Tracking and understanding the application status and problems of labels in a timely manner is of great importance to improving the process route and improving the overall quality of self-adhesive labels. Therefore, it is necessary for material suppliers and printing factories to visit end customers regularly.

To understand the application of the label, the following points should be noted:

① The firmness and wear of the label ink layer;

② Corrosion resistance and shrinkage and expansion of labels;

③The working condition of the label on the labeling machine;

④The weather resistance of the label, whether the ink layer and blank space fade;

⑤Whether the label has edge warping and glue seepage around;

⑥The application of labels on printers or electronic scales.

According to the learned situation, first analyze the cause of the problem, and then further improve the printing and processing technology of the label by modifying the production process route of the label or changing the material type.

The above aspects have comprehensively introduced the influencing factors of self-adhesive printing. In our self-adhesive printing, only by taking these aspects into consideration can we further improve the quality of our self-adhesive printing. We believe that only when the quality is guaranteed can our self-adhesive products be more popular.