Don't miss our holiday offer - up to 50% OFF!

How to choose label paper?

Label paper, also known as self-adhesive label, label printing paper, barcode printing paper, etc., commonly used copper plate label paper, thermal label paper, synthetic paper label, white PET label, dumb silver PET, transparent PET, etc.

As shown in the figure below, the label paper consists of six parts: surface coating, surface material, bottom coating, adhesive silicon coating and backing paper. When we choose label paper, we generally only need to consider three types of surface material, adhesive and backing paper according to our own needs.

Material selection of label paper

1. Choice of surface material

| Type of label paper | Single anti-thermal paper | Three proof thermal paper | coated paper | synthetic paper | Dumb Silver PET |

| Material features | Smooth bright white paper with thermal coating | With heat-sensitive coating, it has good performance in water resistance, blood resistance and grease resistance. | Super-calendered semi-gloss white coated paper. | Matte white polypropylene film, waterproof and tear-proof | Dumb silver polyester film with a uniform special coating on the surface, waterproof and unbreakable |

| Ribbon | No Ribbon Required | No Ribbon Required | Wax-based carbon ribbon, enhanced wax-based, mixed base | Mixed Ribbon | Full resin ribbon |

| Applicable industry | Fruits, FMCG, retail, cash register, etc. | retail, logistics, hospital, etc. | Warehousing, clothing, logistics, medicine, retail, etc. | Warehousing, clothing, logistics, medicine, home appliances, etc. | Banks, real estate, equipment, etc. |

| handwriting preservation time | The storage time is different according to the environment | short storage time | Can be stored for a long time | Can be stored for a long time | Can be stored for a long time |

| Minimum labeling temperature | 10℃ | 10℃ | 10℃ | 5℃ | -4℃ |

| Applicable temperature range | -15℃~+65℃ | -15℃~+65℃ | -15℃~+65℃ | -20℃~+80℃ | -40℃~+149℃ |

More surface material options: writing paper, kraft paper, fragile paper, thermal transfer paper, matte gold paper, bright white PET, repositionable labels, etc.

2. Adhesive Selection

The difference between water-based adhesives and hot-melt adhesives, more options include solvent adhesives, removable adhesives, washable adhesives, etc.

Water-based adhesive, referred to as water glue, is the most widely used in self-adhesive label products. Suitable for most environments and surfaces.

Hot-melt adhesives, referred to as hot-melt adhesives, are suitable for moderate temperature and low temperature environments, and can be pasted on rough surfaces. Label paper cannot be stored for a long time, and the viscosity decays quickly.

In humid environments, water-based adhesives can absorb some moisture, which may reduce tack, but should not be dismissed. If moisture levels prevent the use of water-based adhesives, hot-melt and solvent-based adhesives can be used instead. For more professional options, please contact the distribution department of Unipress label materials.

3. Choice of backing paper

The backing paper of label paper is generally translucent glassine backing paper, which is available in white and blue, and is also the most widely used. If the label paper you purchased is used on a high-speed automatic labeling machine, you need to purchase the label material of transparent PET backing paper.

Classification of tags

The first step in choosing the right label media is to determine the correct form factor. While adhesive labels are likely to be used in most applications, there are other media types that may be better suited.

label

When we refer to “labels” we mean standard self-adhesive type media. All label stock will have some type of adhesive on it and applied directly to the item. Labels are by far the most commonly used barcode carrier medium because they are simple to design and print, and are easy to attach to items. Label stock also comes in a variety of sizes and adhesive types to fit just about anything in any setting.

cloth label

The main difference between cloth labels and labels is that cloth labels do not have any adhesive. Cloth labels are also made from a thicker material than labels. One of the most common uses for cloth labels is clothing hang tags. In any application where the surface is not smooth, you can use other methods such as perforations or staples to attach the labels. Likewise, the use of labels can be beneficial in applications where barcodes need to be removed from items without leaving adhesive residue.

wristband

Wristbands Wristbands are a very reliable barcode carrier, but are also best suited for tracking people. You can put a tag on someone’s clothing, but it’s not a reliable option because it’s more likely to come off. Wristbands are a reliable and easy-to-use method of getting a barcode on a person that won’t come off and can handle the odds of everyday life. Widely used in hospitalized patients.

Selection of label paper specifications

When purchasing label paper, it is also necessary to determine the width and length of the label paper, the inner diameter of the paper tube, the outer diameter of the entire roll, and whether there is a K line, etc. according to the needs.

- The width and length of the label paper are shown in the figure and can be customized according to needs.

- The inner diameter of the paper tube is generally 5cm, 3cm, 4cm, 7.5cm. This needs to be determined according to the label printer purchased.

- The outer diameter of the whole roll also needs to be determined according to the label printer. If the quantity is small, the outer diameter will be small, but if the quantity is too small, it needs to be replaced frequently, so try to increase the quantity of each roll under the premise that it can be put into the printer.

You can inform the customer service of Unipress before purchasing, and we will give you the best recommendation for the label printer model you purchased.

How to print labels

Thermal printers can print in two different ways – direct thermal printing (DT) and thermal transfer (TT). Depending on how long you need the label and its material, one of these two methods will be more effective for your application.

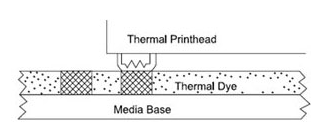

Thermal printing

Direct Thermal (DT) media is printed without any ink or ribbon. The label stock is covered with a heat-sensitive layer that changes color when exposed to the printer’s printhead. Depending on your barcode design, the printhead heats and cools before embossing it into the media. Direct thermal media is known for its simplicity and lower overall cost because the technology prints without the use of ribbon. Direct heat media has a fairly long shelf life (<1 year), but is not suitable for environments exposed to high temperatures, prolonged direct sunlight, or abrasiveness. Printing on direct thermal media still produces sharp images with good scanability. For any short-term application, such as shipping labels, direct thermal is the most effective option.

Thermal transfer

Thermal transfer media does not have a heat-sensitive coating and requires a ribbon (ribbon) that matches the specific material type. In this case, the ribbon is basically fused onto the label media in the pattern of the barcode design. While thermal transfer media does use 2 consumables and has a higher upfront cost, the long term benefits may be cost savings over direct thermal applications. Not only is sublimation transfer media impervious to heat and moisture, but the image won’t rub off, making prints the most durable and longest-lasting option. Since color and density are determined by the ribbon and printer resolution, this method produces consistent, reliable prints on every label. For any application that requires long-term (>1 year) storage of labels such as durable labels, asset tags or wristbands, thermal transfer media will provide you with the most bang for your buck.

Dot matrix printer label

If you didn’t buy a label printer, but you happen to have a dot matrix printer nearby, you can buy computer punched labels. However, it is recommended to purchase a label printer if the printing volume is large.

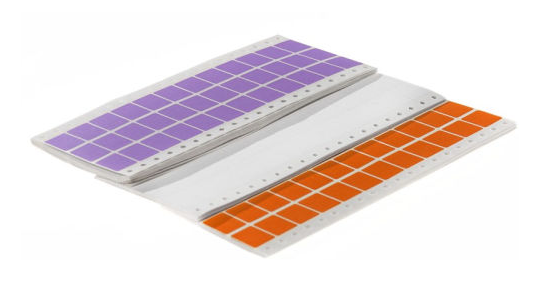

computer punch label

【Product Description】

Self-adhesive labels with perforations on both sides are generally used in dot matrix printers to achieve continuous printing.

Packing method: folding packaging

Holes on both sides: hole diameter 4mm, hole spacing 12.7mm

A variety of colors are available: white is commonly used, and other background colors or pre-printed company logos and other information can also be customized.

Label paper is an important part of any business or organization. It is the paper that is used to print the information on a label. There are many different types of label paper, and it can be difficult to choose the right one for your needs. In this article, we will discuss the different types of label paper and how to choose the right one for your needs.

There are three main types of label paper: thermal, laser, and inkjet. Thermal label paper is used in printers that use thermal transfer printing technology. Thermal transfer printers heat up a ribbon, which then transfers the image onto the label paper. Thermal label paper is generally used for shipping labels or barcodes.

Laser label paper is used in printers that use laser printing technology. Laser printers create an image by melting powdered ink onto a piece of paper. Laser label paper is generally used for labels that need to be printed in high resolution or that have a lot of text.

Inkjet label paper is used in printers that use inkjet printing technology. Inkjet printers create an image by spraying tiny droplets of ink onto a piece of paper. Inkjet label paper is generally used for labels that need to be printed in high resolution or that have a lot of text.

When choosing label paper, you need to consider the type of printer you will be using and the type of labels you need to print. If you will be using a thermal printer, you will need to use thermal label paper. If you will be using a laser printer, you will need to use laser label paper. If you will be using an inkjet printer, you will need to use inkjet label paper.

When selecting label paper, there are a few things to consider. The first is the type of adhesive used on the back of the paper. There are three types: permanent, removable, and repositionable. Permanent adhesive is the most durable and will stay stuck to surfaces over time. Removable adhesive can be removed without damaging the surface, while repositionable adhesive can be moved and reused multiple times.

The second factor to consider is the type of material the label is printed on. The two most common types are paper and vinyl. Paper labels are less expensive but are not as durable as vinyl labels. Vinyl labels are more durable but also more expensive.

The third factor to consider is the size of the label. There are a variety of sizes available, from tiny 1/8″ labels to large 12″x18″ labels. Select a size that best fits the needs of your project.

Once you have considered these factors, you can select the perfect type of label paper for your needs.

When it comes to choosing the right type of label paper for your business or individual needs, there are a few things you need to take into account. The first is what the labels will be used for. There are different types of label paper for different purposes, such as inkjet printing, laser printing, or writing on by hand.

The second thing you’ll need to consider is the weight of the paper. Heavier papers are better suited for labelling items that will be handled frequently or that are exposed to moisture or other environmental elements. If you’re looking for a professional look, you’ll also want to choose a paper with a high-quality finish.

Finally, you’ll need to decide on the size and shape of your labels. There are a variety of standard sizes to choose from, or you can have them custom-made to fit your specific needs. The shape of your labels can also be tailored to your specific needs.

With these factors in mind, you can select the perfect type of label paper for your needs.

Label paper is an important printing material, it is widely used in printing industry. Hangzhou sinoco company is a reliable and professional supplier of label paper. The advantages of Hangzhou sinoco company’s label paper are as follows:

1. Excellent quality

Hangzhou Sinoco company’s label paper is made of high-quality raw materials, so the quality is excellent. It has good printing performance and strong adhesive force, which can meet the requirements of various printing needs.

2. Reasonable price

The price of Hangzhou Sinoco company’s label paper is reasonable, which can save your cost.

3. Fast delivery

Hangzhou Sinoco company always puts the customer’s interests first. We promise to deliver the goods on time.

4. Good after-sales service

If you have any problems with the label paper after receiving it, you can contact us for help. We will solve the problem for you immediately.